Quality Management for Customer Satisfaction

In June 1990, HD Hyundai Electric acquired ISO 9001 certification from QMI, a Canadian quality assurance organization, and has been playing a leading role in quality management in Korea. We are continuously conducting management activities and training to secure the reliability of our quality management system. In addition, through various tests and evaluations conducted by the Reliability Center, the quality of materials/parts is maintained, and the reliability of the final product is secured.

-

Operation of Quality Management System

Acquired international standards ISO 9001 and KEPIC Acquired domestic pressure resistance, ship class, and KS certification

HD Hyundai Electric's quality management system reflects laws and regulations, international standards, and the needs of the market. By acquiring ISO 9001, an international standard for quality management systems, and KEPIC, a nuclear quality assurance system, and maintaining these certifications, we are making continuous efforts to achieve customer satisfaction by acquiring product certifications such as pressure resistance (domestic/overseas), ship class, and KS certification for each of our other products.

-

Product and Service Safety Policy

Provision of manual when products are shipped

We provide product manuals at the time of shipment in order to ensure safety while use our products and services in the field and to ensure the proper implementation of our products. In particular, regarding the major causes of climate change (such as SF6 gas for insulation), we are sparing no efforts to protect customer assets and prevent environmental pollution by providing detailed information such as the degree of environmental impact, handling precautions, and disposal methods.

-

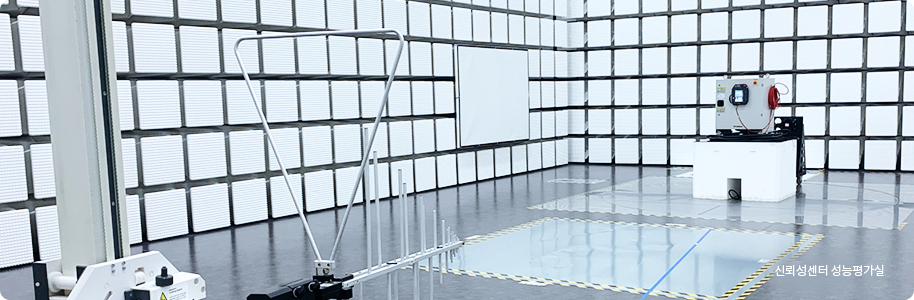

Operation of Reliability Center

Conducts more than 300 product technology-related tests per year and strengthens internationally recognized testing and certification systems such as KOLAS AND UL CTF

The Reliability Center is playing a pivotal role in improving product quality and reliability by conducting a total of 330 tests in 2020. We plan to secure reliability evaluation technology for eco-friendly products and to establish a certification system through collaboration with external research institutes in 2021. In addition, by expanding the scope of Korea Laboratory Accreditation Scheme (KOLAS) accreditation, we plan to continuously strengthen the systems of internationally accredited testing institutions and add KOLAS accreditation for high-efficiency low-voltage motor products.