R&D Status

Increase business productivity through R&D and effectively establish a technology diffusion system.

R&D Loaction

HD Hyundai Electric has achieved remarkable global growth every year by increasing business productivity through R&D and establishing an effective technology diffusion system.

- 2019

-

Reliability Assessment Center, KOLAS Accredited by an accredited certification body

- 2018

-

New office opening of Hyundai Technologies Center Hungary Kft.

Reliability Assessment Center opened to enhance R&D capability

- 2017

-

Hyundai Electric Switzerland Ltd. established

Hyundai Electric Research Institute established

- 2012

-

Electro Electric Systems Division research institute launched

- 2011

-

Research institute established in China

- 2002

-

Mabuk-ri Research Institute was renamed Hyundai Electro-Mechanical Research Institute

- 1998

-

Research institute established in Hungary

- 1997

-

Central Research Institute was renamed Mabuk-ri Research Institute

- 1994

-

Merged into Hyundai Heavy Industries’ General Research Institute and Hyundai Heavy Industries Co., Ltd.

- 1982

-

Hyundai Electrical Engineering Co. Technology Institute established

- 1978

-

Hyundai Electrical Engineering Co. spin-off

- 1977

-

Hyundai Heavy Industries Co., Ltd. establishes Electrical Engineering Division

Key Products·Development

-

Transformers

Development of cost innovation model for large-capacity power transformers

Development of small and medium-sized transformers up to 170 kV

Development of insulation material manufacturing technology and cost reduction design technology

Development of coupled magnetic field and vibration analysis, as well as thermal analysis/evaluation technology and material analysis

-

Gas Insulated Switchgear

Development of self-blast type circuit breakers and product line-up

Development of GIS for the high voltage/current HVDC

Development of GCB line-up for AIS

Development of Eco-friendly SF6-free 170kV, 50kA GIS and core technology

-

Rotating Machinery

Product line-up establishment and standardization through Value engineering for high/low voltage motors, low voltage generators

Product line-up establishment and quality standardization for shaft machine(PTO/PTI) and premium efficiency motors

Development of design optimization technology with analysis of electromagnetic, thermal fluid and structural

Establishment of asset management service system for rotating machinery with ICT

-

Power ICT

Development of smart electro electric Vertical Applications

Development of next-generation ACONIS operating platform for expanding into LNG carrier market

Procurement of engineering and EMS control technology for new energy projects

Development of electrical engineering technology for ordering, design, testing, and operation of electric power equipment

-

MV/LV Switchgear

Development of cost reduction model for expansion into new markets and better revenues : MCSG, LV/MCC

Development of next-generation ICT-ready smart switchboards through convergence with ICT

Development of VCS for ships, MCSG for nuclear power plants, etc.

Standardization of switchboard design and development of engineering technology

-

MV/LV Circuit Breaker

Development of smart electro electric inter-compatible product family

Expansion of HG Series product line

Development of electric arc and vacuum arc analysis technology for cost reduction and downsizing

Development of intelligent protection-relay and measurement products

-

Drive Systems

Development of standard low-voltage drive system(0.5 - 132kW)

Development of compact low-voltage drive system(0.5 - 22kW)

Development of drive system(3.3/4.16kV, up to 8MW) for electric propulsion in ships

Improvement of application technology according to load characteristics(fans, air conditioners, mixers, cranes etc.)

-

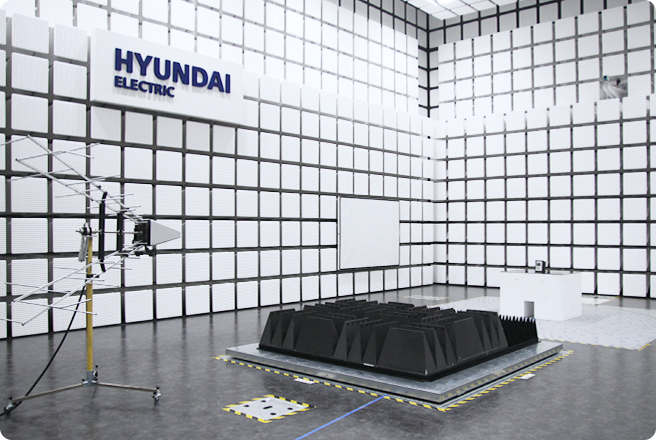

Quality and Reliability

Erection and Management of Electro Electric Systems Reliability Center

Establishment of reliability and environmental testing techniques for electro electric systems

Improvements of design, production, and testing processes of electric machinery